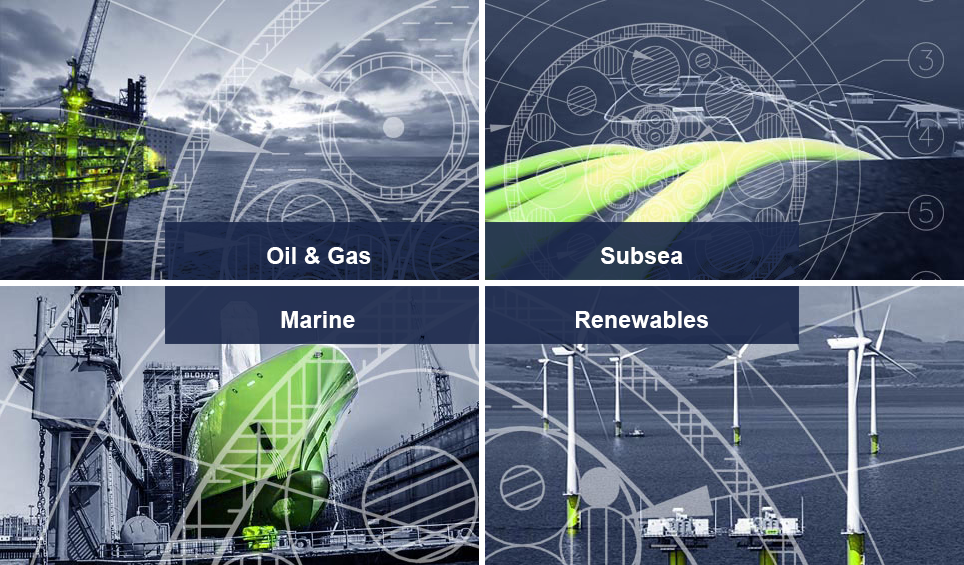

Oil & Gas / Subsea / Marine / Renewable Energy.

Cable Solutions design and manufacture topside and subsea composite cables, umbilicals and tethers for a wide range of offshore oil & gas, marine, subsea and renewable energy projects. Our composite cables connect multiple support elements of an offshore energy field, providing power, control and monitoring.

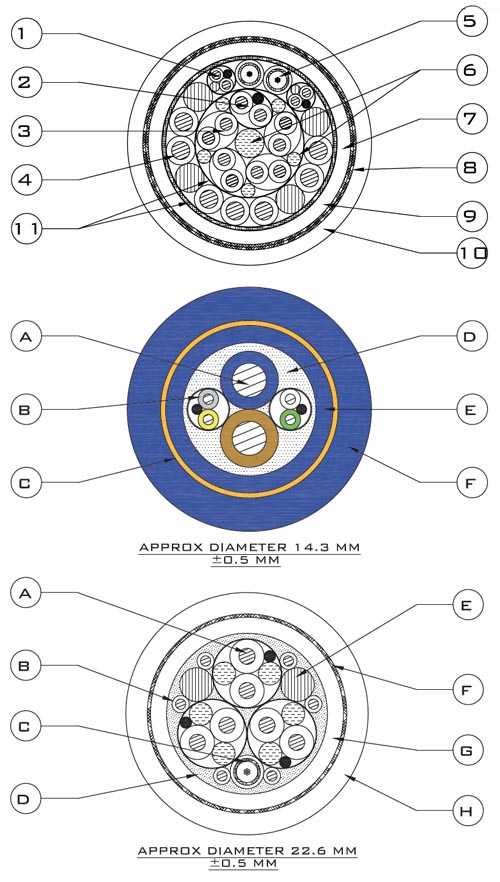

Below is a small sample of our Composite Cable designs - electrical / fibre optic and hybrid. Please contact us regarding your cable requirement, we design and manufacture most composite cable configurations.

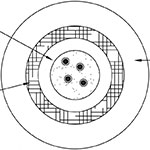

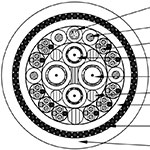

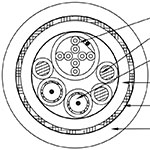

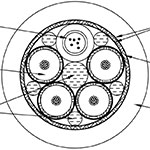

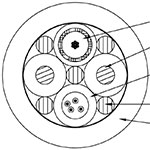

16.7mm O/D - MDPE bedding sheath - galvanised wire braid - MDPE sheath

16.7mm O/D - MDPE bedding sheath - galvanised wire braid - MDPE sheath 11.8mm O/D - 0.34sqmm twisted foil screened pair - polyurethane sheath

11.8mm O/D - 0.34sqmm twisted foil screened pair - polyurethane sheath 16.0mm O/D - 0.5sqmm twisted screened pair - polyurethane sheath

16.0mm O/D - 0.5sqmm twisted screened pair - polyurethane sheath 16.5mm O/D - 1.5sqmm conductor - polyurethane sheath

16.5mm O/D - 1.5sqmm conductor - polyurethane sheath 12.8mm O/D - 2.5sqmm conductor - polyurethane sheath

12.8mm O/D - 2.5sqmm conductor - polyurethane sheath 15.5mm O/D - 0.22sqmm twisted screened pair - hot melt encapsulate bedding - polyurethane sheath

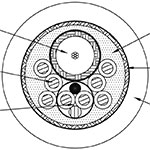

15.5mm O/D - 0.22sqmm twisted screened pair - hot melt encapsulate bedding - polyurethane sheath 28.6mm O/D - gel filled PBT tube with 12 fibres - 50/125 multimode - polyurethane sheath

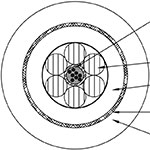

28.6mm O/D - gel filled PBT tube with 12 fibres - 50/125 multimode - polyurethane sheath 6.0mm O/D - gel filled PBT tube with 2 x sm 9/125 + 2 x 62.5/125 fibres - colour codeds - galvanised steel wire braid - SHF2 outer sheath

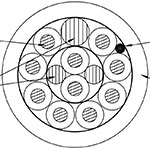

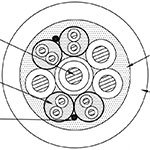

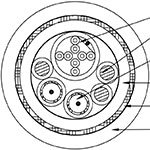

6.0mm O/D - gel filled PBT tube with 2 x sm 9/125 + 2 x 62.5/125 fibres - colour codeds - galvanised steel wire braid - SHF2 outer sheath 30.5mm O/D - 8 fibres 9/125 singlemode - PE jacket - 4 cores 1.5sqmm - 10 TSP's - 2 RG59 coaxials - 2 x RG58 coaxials - galvanised wire - ZHFR PU sheath

30.5mm O/D - 8 fibres 9/125 singlemode - PE jacket - 4 cores 1.5sqmm - 10 TSP's - 2 RG59 coaxials - 2 x RG58 coaxials - galvanised wire - ZHFR PU sheath 13.6mm O/D - 8 fibres 62.5/125 multimode - hydrogen scavenging gel - PU bedding - aramid braid 1000kg - PUR outer sheath

13.6mm O/D - 8 fibres 62.5/125 multimode - hydrogen scavenging gel - PU bedding - aramid braid 1000kg - PUR outer sheath 5.0mm O/D - 1 gel filled PBTB nylon - 2 fibre optic tubes 9/125 singlemode - kevlar braid 300kg - polyurethane sheath

5.0mm O/D - 1 gel filled PBTB nylon - 2 fibre optic tubes 9/125 singlemode - kevlar braid 300kg - polyurethane sheath 10.6mm O/D - fibre optic cable tight buffer - 4 singlemode fibres 9/125 - galvanised steel wire braid - zero halogen flame retardant polyurethane sheath

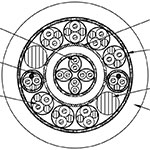

10.6mm O/D - fibre optic cable tight buffer - 4 singlemode fibres 9/125 - galvanised steel wire braid - zero halogen flame retardant polyurethane sheath 17.1mm O/D - 2 x 9/125 - 2 x 62.5/125 colour coded - 2.5sqmm conductors - vectran braid -tinned copper braid - galvanised wire braid - zero halogen flame retardant polyurethane sheath

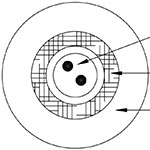

17.1mm O/D - 2 x 9/125 - 2 x 62.5/125 colour coded - 2.5sqmm conductors - vectran braid -tinned copper braid - galvanised wire braid - zero halogen flame retardant polyurethane sheath 14.0mm O/D - 0.24sqmm CAT5 foil tape screened data pairs - 0.24sqm drain wires - hot melt encapsulated layer - 1.5sqmm conductor - zero halogen polyurethane sheath

14.0mm O/D - 0.24sqmm CAT5 foil tape screened data pairs - 0.24sqm drain wires - hot melt encapsulated layer - 1.5sqmm conductor - zero halogen polyurethane sheath 12.5mm O/D - CAT5 SF/UTP ethernet cable - RG1 79 HF coaxial - 0.75sqmm and 0.5sqmm conductor - tinned copper wire braid - LSOH polyurethane sheath

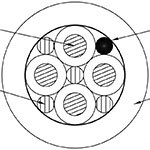

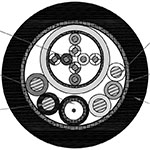

12.5mm O/D - CAT5 SF/UTP ethernet cable - RG1 79 HF coaxial - 0.75sqmm and 0.5sqmm conductor - tinned copper wire braid - LSOH polyurethane sheath 21.6mm O/D - 1.0sqmm conductor - 0.5sqmm twisted screened quad / RG59 coaxial - zero halogen flame retardant polyurethane sheath

21.6mm O/D - 1.0sqmm conductor - 0.5sqmm twisted screened quad / RG59 coaxial - zero halogen flame retardant polyurethane sheath 14.1mm O/D - gel filled PBT tube - HDPE jacket - RG58 coaxial - vectran braid - zero halogen flame retardant polyurethane sheath

14.1mm O/D - gel filled PBT tube - HDPE jacket - RG58 coaxial - vectran braid - zero halogen flame retardant polyurethane sheath 12.5mm O/D - 75OHM RG59 hybrid coaxial - 0.5sqmm conductor - 0.5sqmm twisted screened pair - hot melt encapsulate bedding - PU fibre braid 150kg - polyurethane sheath

12.5mm O/D - 75OHM RG59 hybrid coaxial - 0.5sqmm conductor - 0.5sqmm twisted screened pair - hot melt encapsulate bedding - PU fibre braid 150kg - polyurethane sheath 14.1mm O/D - CAT5 FTP patch cable - power conductors - polyurethane bedding sheath - galvanised steel wire - polyurethane sheath

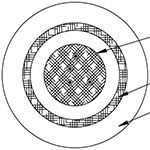

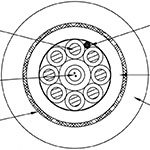

14.1mm O/D - CAT5 FTP patch cable - power conductors - polyurethane bedding sheath - galvanised steel wire - polyurethane sheath 19.1mm O/D - CAT5 S/FTP 4 pair screened - 0.22sqm twisted screened pair - 0.22sqm twisted pair - vectran strength member 300kg - tinned copper wire braid - polyurethane sheath

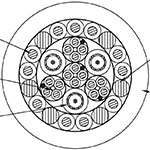

19.1mm O/D - CAT5 S/FTP 4 pair screened - 0.22sqm twisted screened pair - 0.22sqm twisted pair - vectran strength member 300kg - tinned copper wire braid - polyurethane sheath 12.0mm O/D - 0.5sqmm conductor - gel filled PBT tube / 3 fibres 9/125 singlemode - polyurethane bedding - vectran braid 1250kg - polyurethane sheath

12.0mm O/D - 0.5sqmm conductor - gel filled PBT tube / 3 fibres 9/125 singlemode - polyurethane bedding - vectran braid 1250kg - polyurethane sheath 10.8mm O/D - 2 conductors 1.0sqmm 32/0.2 - 1 fibre optic cable PBT tube 4 fibres 62.6/125 multimode - polyurethane sheath

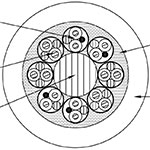

10.8mm O/D - 2 conductors 1.0sqmm 32/0.2 - 1 fibre optic cable PBT tube 4 fibres 62.6/125 multimode - polyurethane sheath 16.3mm O/D - CAT5 FTP patch cable - 3 cores - 2 RG59 coaxials - ZHFR polyurethane bedding - galvanised steel wire braid - ZHFR polyurethane sheath

16.3mm O/D - CAT5 FTP patch cable - 3 cores - 2 RG59 coaxials - ZHFR polyurethane bedding - galvanised steel wire braid - ZHFR polyurethane sheathCable Solutions Worldwide specialises in the design, manufacture and supply of topside and subsea composite cables. Known for bespoke cable design solutions and driven by exceptional customer care, Cable Solutions are able to deliver short cable lengths to customers for project trials. Please ask for details.